BW Series

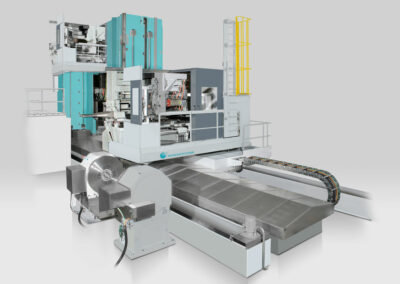

Milling and deep hole drilling centers

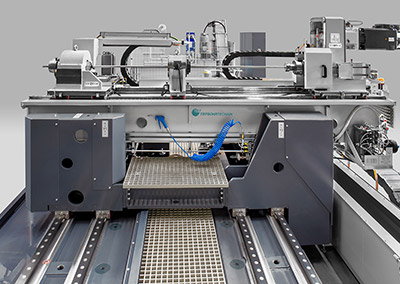

Our deep drilling centers for your drilling, milling and tapping applications ensure maximum productivity. We will be happy to advise you on which of our concepts meet your specific requirements.

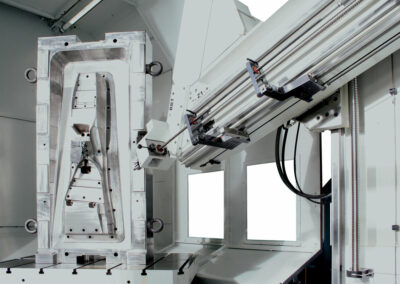

The BW250 series offers you an optional tool changing system and conventional tools. In addition, long deep drilling tools can be changed fully automatically without manual intervention.

Drilling, milling, tapping for e.g. heat exchanger bases and plates.

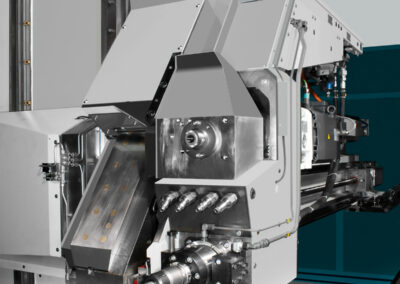

Type BW250-S

1 spindle (stepless drive)

3-35 mm (ELB) & 40 mm (inserts) drilling diameter

1500 mm max. drilling depth in one pass

15000 kg payload centric

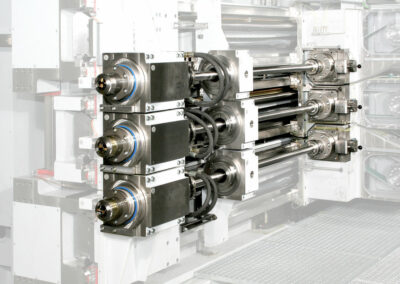

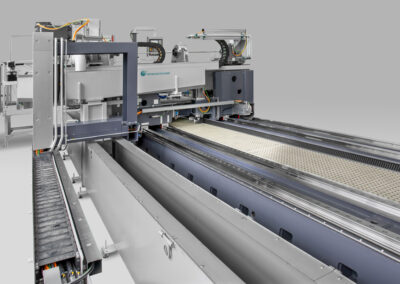

Typ BW500 for heat exchanger plates

1-3 spindles

10-32 mm (ELB) & 15–62 mm (BTA/STS) drilling diameter

1200 mm drilling depth

Our BW series for drilling, milling and thread cutting – a perfect fit for your application

.

Injection molds, graphite blocks, pipeline elements and fittings, hydraulic control plates, large components, heat exchangers …