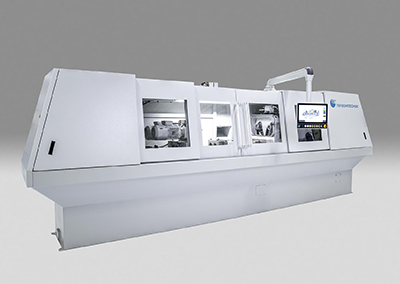

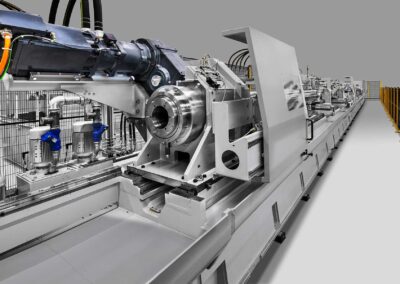

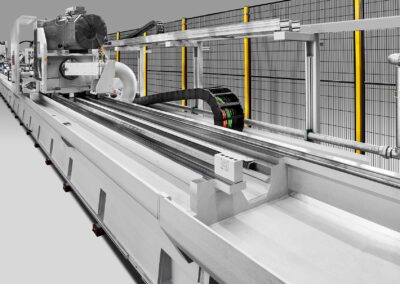

ML Series

Horizontal machines – multi-spindle

The ML series is a true all-rounder in deep-hole drilling technology. Whether with one or six spindles, whether with 0.8 or 400 millimeter drilling diameter – it convinces with versatility, precision and durability. We will be happy to advise you on which of our ML machines is suitable for your application. Call us and, if you wish, arrange a viewing appointment right away.

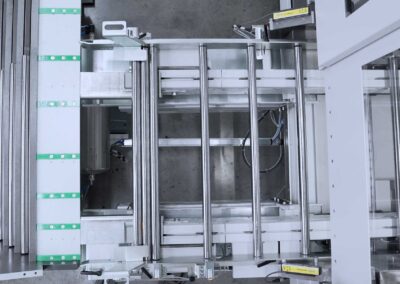

Standard and customized solutions for automatic loading and unloading of workpieces are a matter of course

Deep hole drilling processes with reduced quantity lubrication can be realized with these machines without any problems

Type ML200

ELB drilling method

1-4 spindles

0,8-12 and 2-18 mm drilling diameter

400 / 700 mm drilling depth

Type ML250

ELB drilling method

1-4 spindles

1-12 and 4-30 mm drilling diameter

450 / 650 / 1250 / 1550 mm drilling depth

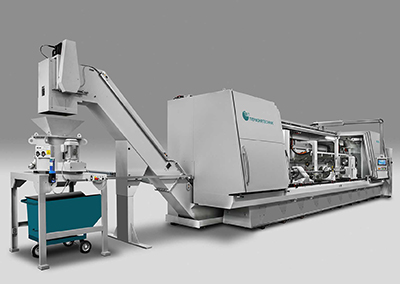

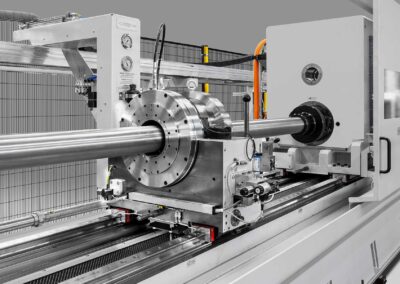

Type ML500

ELB (on request), STS/BTA drilling method

1-6 spindles

15-90 and 15-180 mm drilling diameter

1000-7000 mm drilling depth

larger drilling depths on request

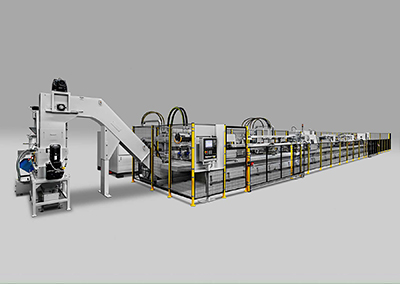

Typ ML700

STS/BTA drilling method

1 spindle

15–150 and 15–400 mm drilling diamteer

1000–15000 mm drilling depth

Larger drilling depths on request

As diverse as our ML series deep hole drilling machines are, so are the fields of application

Common rail, transmission shafts, wheelset shafts (traction axles), rocker arm axles, valves, connecting rods, cylinder blocks/heads, injectors, pressure pipe nozzles, injection pump bodies, piston rods, camshafts, aircraft landing legs, matrices, bone nails & screws, medical instruments, hydraulic cylinders, molds, tool shafts, heat exchanger bases, centrifugal casting pipes, castors …